Following on from my previous post about fonts for painting, I wanted to put together a list of my favourite typefaces that are reminiscent of drawing styles.

Typefaces for artists: fonts for drawing

Typefaces for drawing often draw on (sorry) a particular style of broken or wavering line quality that immediately suggests the involvement of an imperfect human hand.

Although that’s not the one and only thing that denotes a hand-drawn mark, it’s one of the features that catches our interest and tells us straight away what this typeface is about.

We think of hand-drawn lettering as honest, simple and pure: the most down-to-earth, natural form of art we can produce. So even if your project has nothing to do with art but needs to pinch some of that creative mythos, these fonts are an ideal place to start.

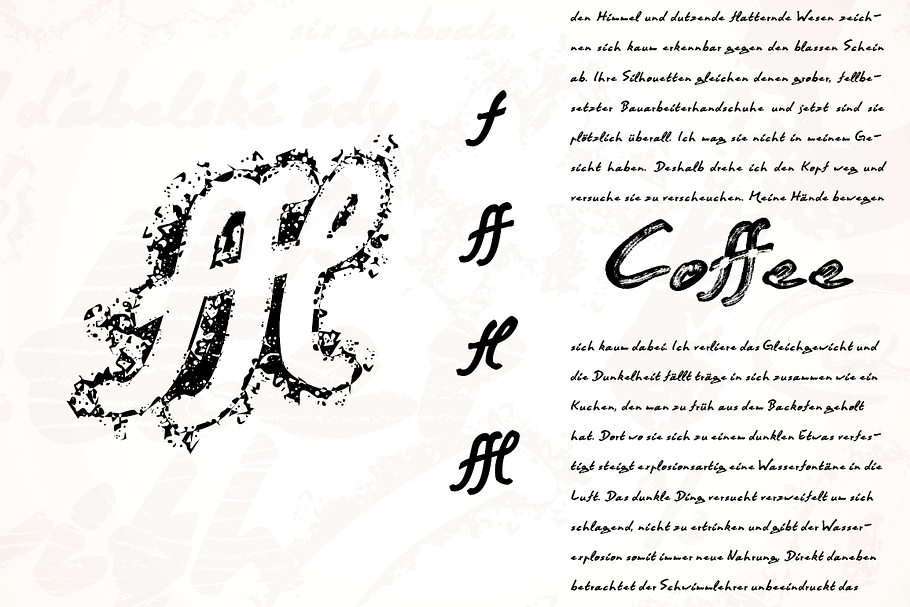

Macarons Font Family

Macarons is a hand-drawn font package that comes in five weights:

- Macarons Light

- Macarons

- Macarons Bold

- Macarons Sketch

- Macarons Bold Sketch

There’s also a set of “catchwords” and ornaments included. I really like this typeface – it has a serious tone to its form that’s undercut by its wibbly-wobblyness. It’s as though Times New Roman stopped taking its medication.

Even better, it looks as though it could lend itself well to linocut or woodcut styles.

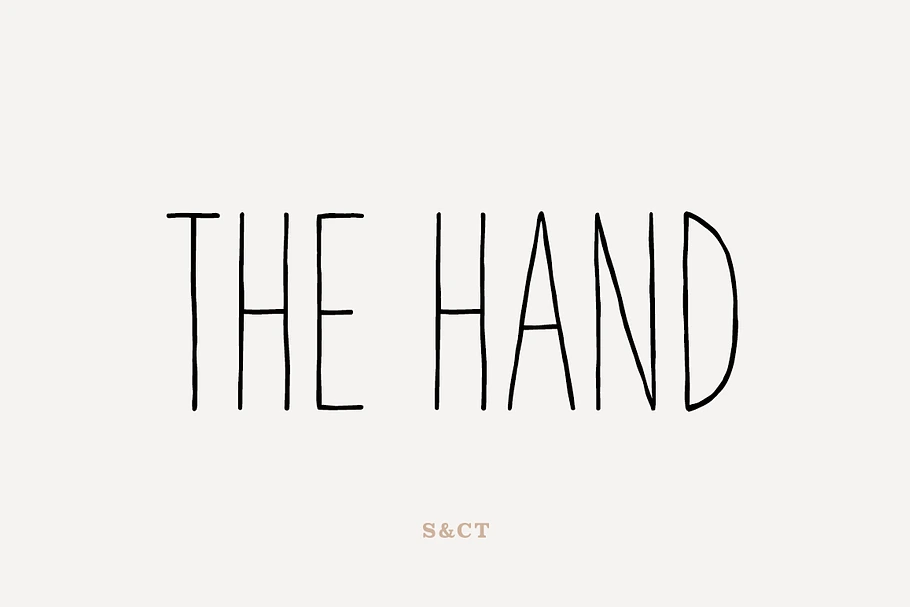

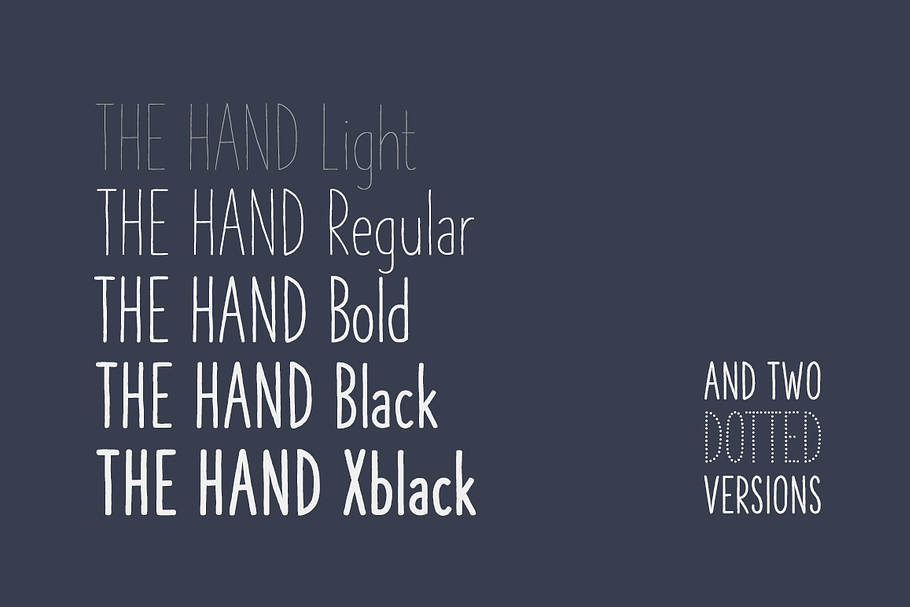

The Hand Font Collection

The Hand Font Collection contains 7 fonts in different weights – light, regular, bold, black, xblack and two dotted versions. That’s a great package that covers a range of styles.

The Hand Light is reminiscent of the faint trace of a mechanical pencil (reminds me of Technical Drawing at school) or fineliner, whereas The Hand Xblack gives you an impression of wielding a felt-tip marker.

The dotted versions are great for complementing stippled effects.

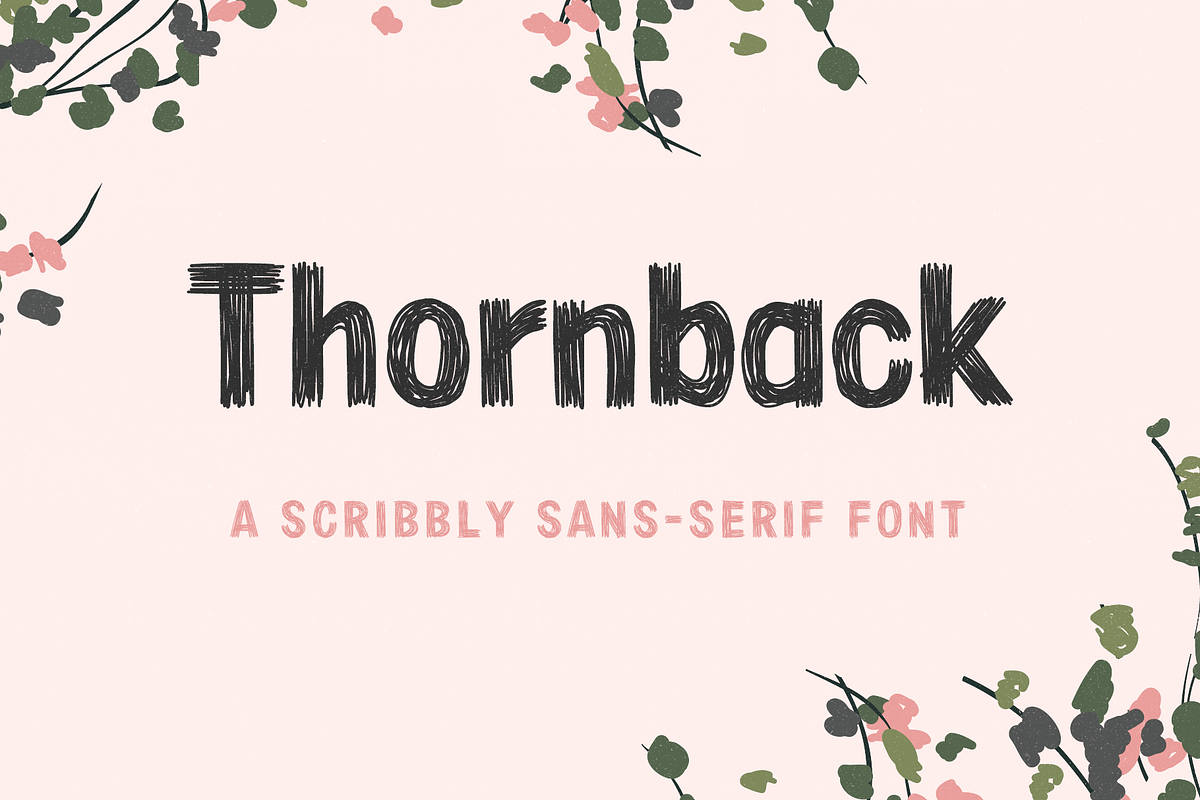

Thornback

Thornback is an extremely charming scribbly font that somehow reminds me of the Sunday comics, but at the same time could just as easily be tipped over the spiky edge of anarchy.

It’s a great typeface for anyone who wants to keep it loose, but still maintain and element of control – this has both.

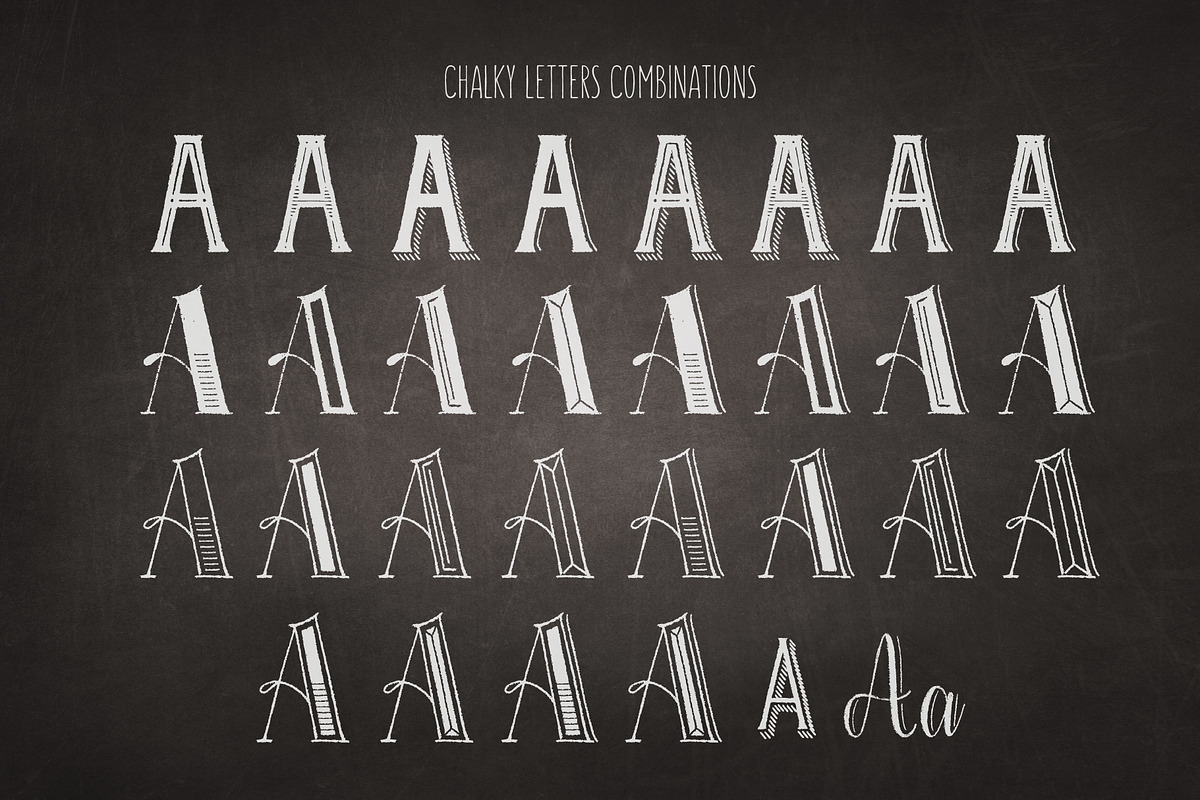

Chalky Letters font collection

The Chalky Letters font collection has a beautiful, delicate illustrative quality to it, and it’s amazing how many combinations you can make.

This collection contains 17 fonts in all, including a set of decorative extras. It’s hard to imagine getting through all of the possible combinations!

I’m really impressed by this font package. Also, with just a bit of imagination this could be effectively used to illustrate other dry media such as pastel and charcoal – it doesn’t have to be all white-on-black.

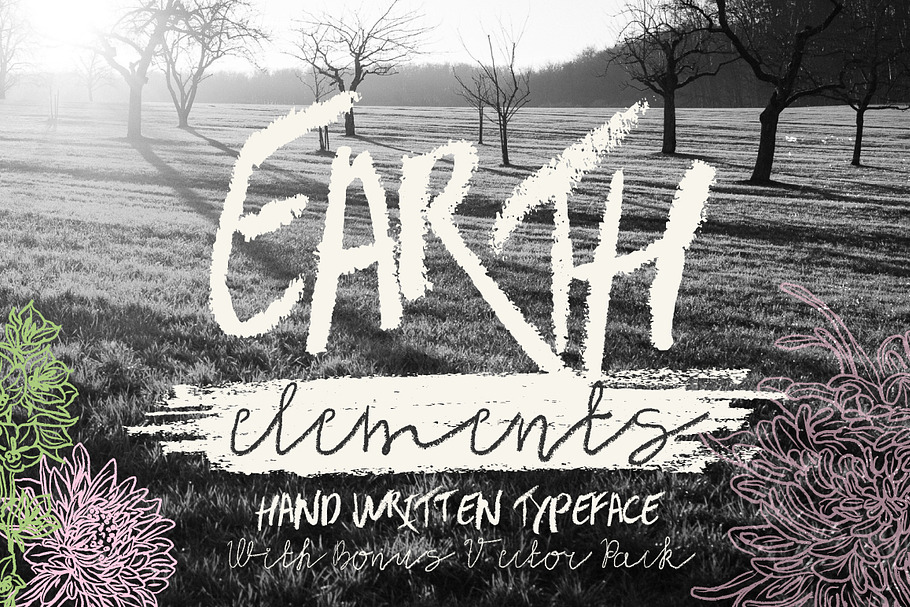

Earth Elements Typeface

I almost bypassed Earth Elements, as the jagged lines of the chalky capitals didn’t quite grab me at first. However, once I saw the quirky, flimsy lines of Earth Element soft, the script type included in this package, I was hooked.

The soft script reminds me of doodling with a 6B pencil on not-pressed paper, and the regular script looks like a charcoal attack. It’s a fantastic duo, and the bonus vector pack has some great, smudgy elements to complement the text.

Faun Font Duo

Faun is a fun, over-the-top, impressive decorative display font. It would be absolutely perfect for accompanying adult colouring books or for working alongside a strong graphic style, but beware – something this big and bold can easily overshadow artwork and steal the show, so use wisely!

Quendel Happy Family Fingertip

I’m glad that I found Quendel Happy Family Fingertip – it’s not easy to figure out what’s going on with this font thanks to the confusing imagery which shows all four of the fonts available in this “family”, but this one is the Fingertip version only.

It’s a negative space typeface – imagine drawing with your finger on the beach, or pushing around some graphite dust on a smooth board. I think it’s really interesting and gets to the heart of mark-making.

My fonts for drawing have incorporated styles reminiscent of finger painting, pencil, charcoal, fineliner and chalk – I’m pretty pleased with that! I hope it’s helped you as well.

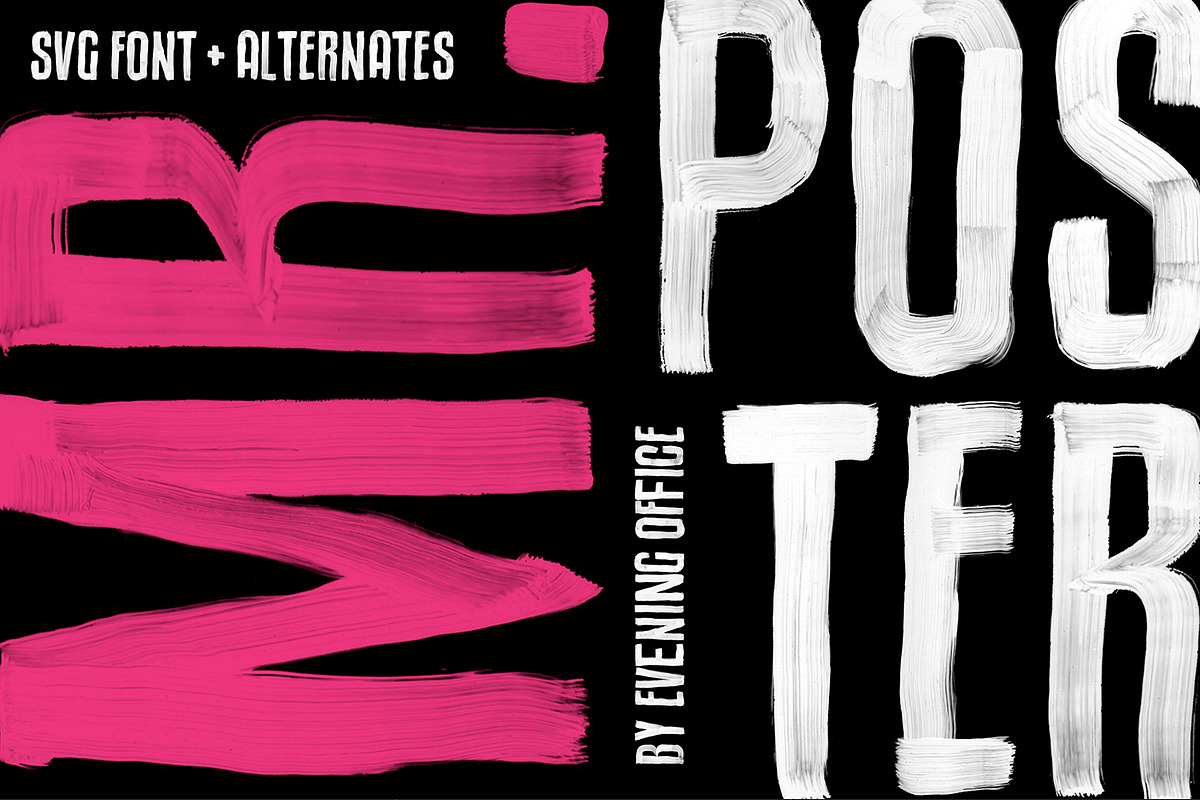

More like this: fonts for painting.