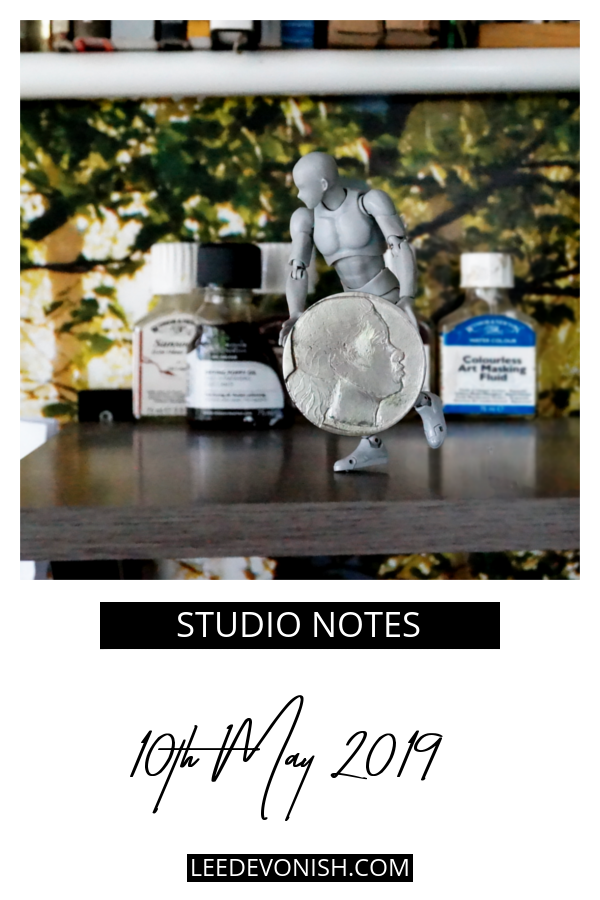

Studio notes 10/05/19 - can you use a plotter cutter as a 3d printer hack? This week I've worked on new coin sculpture and restretched aluminium screens.

What a busy week – redesigning the pewter coin has been the most important thing, but I’ve squeezed in a few jobs on the side as well, like re-stretching an aluminium screen and prepping materials for a new miniature sculpture.

Last week I had planned to restretch a couple of screens using two-part evil glue, but when I finally got an afternoon of dry weather and opened up the bottles, I realised that the hardener had – well – hardened, and it was unusable.

My ghetto screen stretching method

All of this after I’d started the process: I tacked the mesh across a wooden frame that was just bigger than the aluminium frame, laid it on top of the aluminium frame and clamped it tightly down onto it. That would stretch the mesh even tighter over the new frame and allow me to glue the mesh and screen surfaces.

That way I’d get a very taut, professional-quality stretch in my back garden. Well, that was the plan until the glue problem, so having set everything up – clamps and all – I just went ahead with contact cement.

So far so good – I sliced the screen out of the wooden frame and it’s kept its tension, but I’m going to have to test its resistance to all the screen printing processes. And… I’m out of mesh for this size of screen, so I’ll have to buy some more before I can carry on.

Back to sculpting the coin

When I started the process of sculpting coins last year I came up against the problem of creating precise marks in materials that don’t lend themselves to the level of precision that I wanted.

Everything I did was made the old-fashioned way: all hand carved, with the most advanced process being photocopying. This is kinda how I roll; my natural inclination is to do everything without computers, not because I have to prove something, but because that’s just how I learned to do things and that’s what comes naturally. If I’m going to push this to where it needs to go, that has to change.

The point isn’t to create industrially manufactured pieces, but to marry the idea of a hand-made object of value with that of a mass-produced symbol of value. Basically I need to upgrade my processes.

With modern coin design and manufacture, you can’t get away from computers and machines. I’ve been thinking about ways to incorporate more computer-assisted working into my practice, whether it’s getting a 3d printer or – as an alternative – a plotter cutter.

I’ve spent the last week researching these and it’s made my head spin. The thing is, they’re pitched firmly at the crafts market, and it can be hard to figure out if the machine you’ve spotted will be suitable for more robust work, or, more importantly, original work (not being restricted by locked-in software).

My plan is to use one of these to precision-cut paper layers to laminate sculptural forms. It’s not that out of the question – it’s basically how I’ve been forming my new coin this week, but by hand. Maybe before too long I’ll have a bit of help with that.

Leave a Response